We Bring Intelligence To All Endpoints

Our sensing solutions now make it possible to connect "everything" and bring intelligence to every "endpoint" in a system.

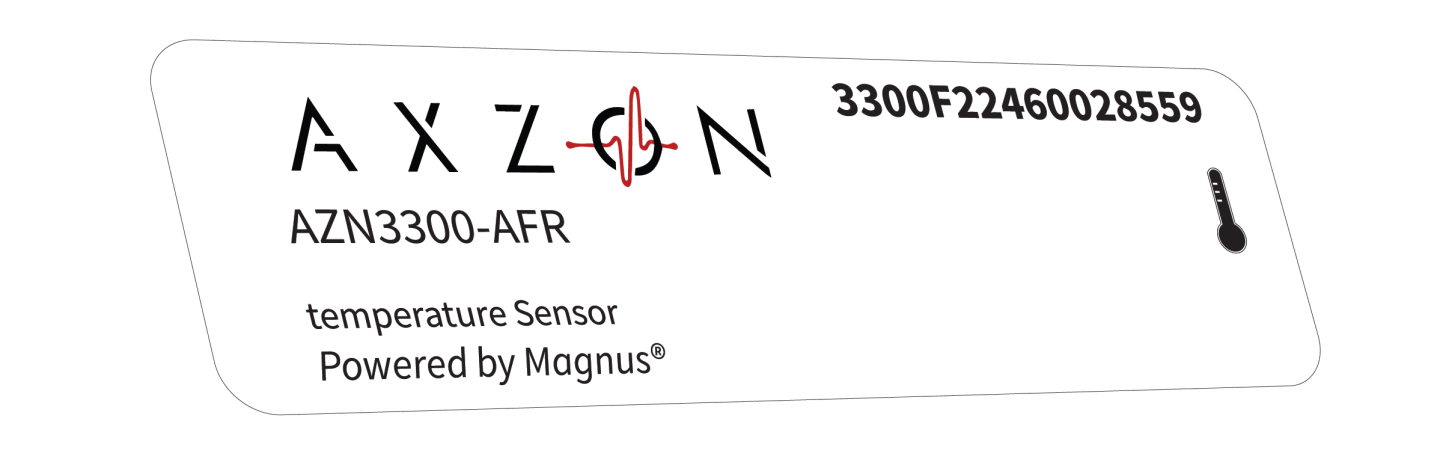

Our patented sensors technology requires no batteries or wires and communicates wirelessly to a reader over a distance of as much as 19 meters. Now, temperature and moisture data can be collected and wirelessly transmitted to a local hub or cloud platform for analysis and action.

With our low cost Peel & Stick sensor attaching them exactly to where you need to gather data (endpoints) is now possible.